is part of the FACULTY of MECHANICAL and POWER ENGINEERING

at Wrocław University of Technology

There are about 20 researchers in the Department incl. 2 professors

The head of the Department is prof. Halina Pawlak–Kruczek

RESEARCH INTERESTS are presented below

Energy and fuels

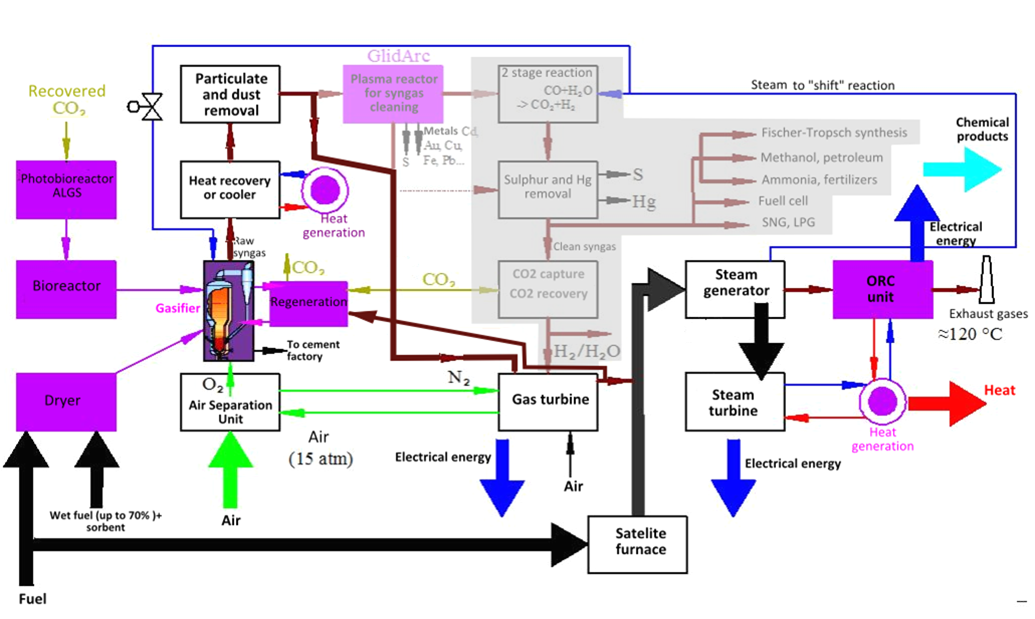

Fuel processing: combustion, gasification, pyrolysis and torrefaction and drying of solid fuel including biomass:

Advanced power generation: zero emission technology CCS – and oxyfuel:

Renewable fuels (hydrogen production, solid biomass and liquid biomass) fossil fuels (hard coal and lignite)

Mechanical engineering

Renewable energy

Micro and mid power system applying of biofuels and solar sources

Bioenergy

Solid biomass: combustion, gasification, pyrolysis, torrefaction, biochar: liquid biofuels including by-products such as glycerol

Thermodynamics

Kinetics, equilibrium

Environmental energy

Low emission technology, flue gas cleaning, sustainable energy, utilization of wastes

Energy engineering

Process integration, process system engineering, energy efficiency, chemical looping combustion

CO2 capture, CO2 separation, absorption, advanced solvent system, novel solvents and dry sorbents

Modeling of power producing processes including combustion, fouling slagging, desulfurization

Projects and Research Conducted in Department — overview

Future Clean Energy Valley

Project conducted within National Center of Power Generation Technologies.

DRYLIG – Competitive Pre-Drying Technologies and Firing Concepts for Flexible and Efficient Lignite Utilization

Project conducted in cooperation with CPERI/CERTH (Chemical Process and Energy Resources Institute / Centre for Research & Technology Hellas).

Dryer in pilot scale, fluid-spouted bed dryer, output 150 kg/hr.

MODELING AND COMPUTER AIDED DESIGN OF POWER DEVICES

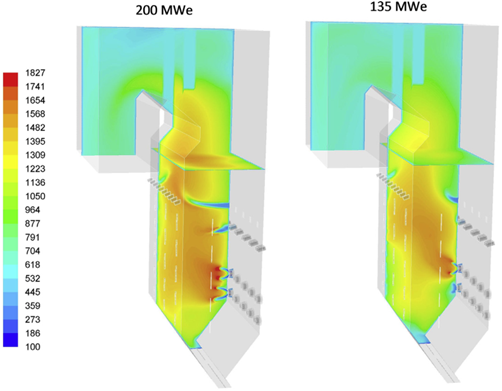

Research area: combustion technology in boilers, CFD simulations, modeling of power plant elements, energy systems modeling, analysis of the on-line measuring system data.

Latest research:

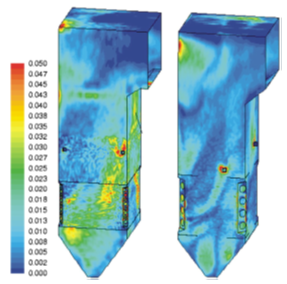

- Deposits formation in large scale coal-fired boilers

- implementation of deposition model into Ansys Fluent

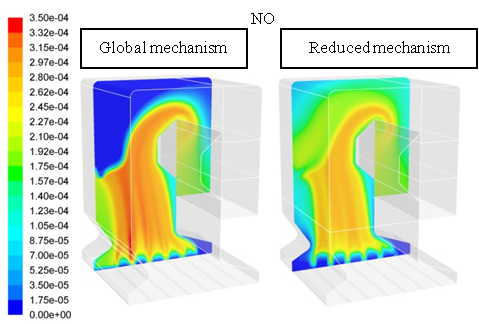

- Numerical Simulation of SNCR Process (chemical kinetics)

- implementation of skeletal reaction mechanism into Ansys Fluent, comparison of skeletal with standard (global) mechanism in coal fired grate boiler

- A validation of computational fluid dynamics temperature distribution prediction in a pulverized coal boiler with acoustic temperature measurement

project related to combustion process optizmiation in front fired boiler

Deposit thickness (mm) in two boilers

SNCR Mechanisms performance in CFD simulations

Temperature contours (⁰C).

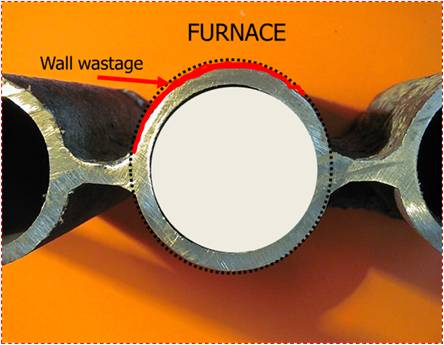

RISK ASSESSMENT FOR CORROSIVE BOILER FURNACE

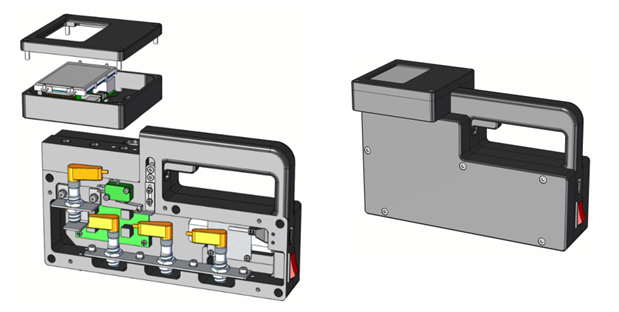

DRON WITH CAMERA TO INSPECT ON-LINE CURRENT STATUS OF ANY SURFACE ( DEPOSITS, WASTAGE ..)

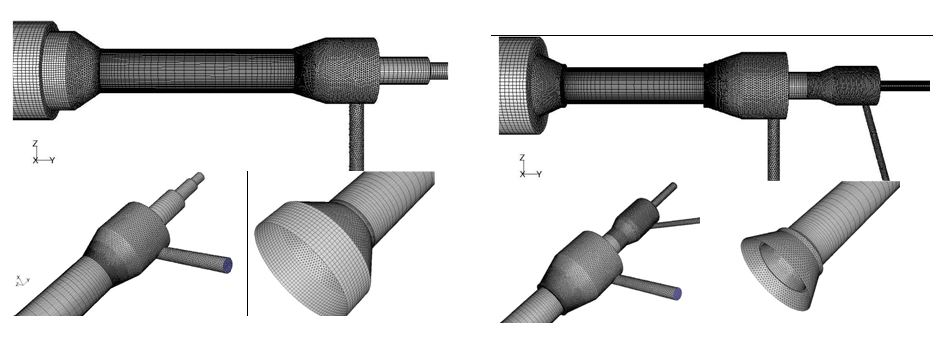

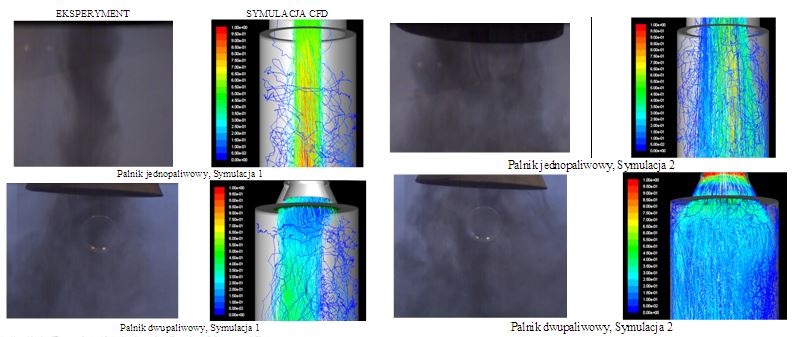

BURNER – RESULTS FROM PHYSISCAL AND NUMERICAL MODELLING

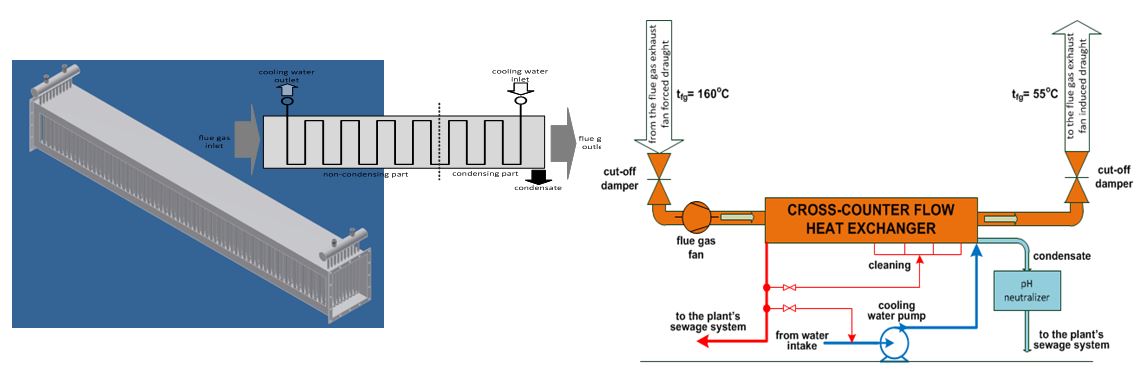

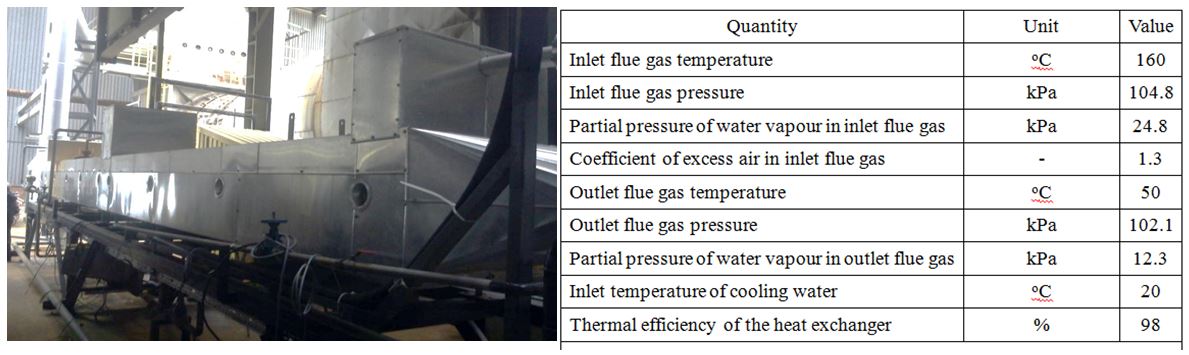

Condensation of Steam Contained in Flue Gas

See here for detailed list of laboratory equipment and research stands

To achive more information please contact head of the Department:

prof. Halina-Pawlak Kruczek

room. 253; build. A-4

e-mail: halina.kruczek@pwr.edu.pl

tel. +48 71 320 39 42